In Nigeria’s industrial heartland of Port Harcourt, the demand for skilled automation professionals continues to surge as oil and gas companies, manufacturing plants, and power generation facilities embrace digital transformation.

At the center of this industrial revolution lies the Programmable Logic Controller (PLC)—a critical technology that drives process automation, enhances operational efficiency, and ensures workplace safety across diverse sectors.

RemtronicAutomations stands as Port Harcourt’s premier hands-on training provider, equipping engineers, technicians, and technical graduates with practical PLC programming skills that meet real-world industrial demands.

Located at 17b Hon. Gideon Street, Off Peter Odili Road, Port Harcourt, RemtronicAutomations offers comprehensive training programs designed not just to teach theory, but to prepare participants for immediate deployment in industrial automation roles.

With state-of-the-art laboratory facilities, experienced instructors, and a curriculum covering multiple PLC brands, the training center bridges the critical gap between academic knowledge and industry requirements.

What is PLC Programming?

A Programmable Logic Controller is a specialized industrial computer designed to control manufacturing processes, machinery, and automated systems in harsh industrial environments.

Unlike conventional office computers, PLCs are built to withstand extreme temperatures, vibrations, electrical noise, and moisture while executing control logic with millisecond precision.

These rugged controllers monitor inputs from sensors and switches, process information according to programmed instructions, and activate outputs such as motors, valves, pumps, and conveyor systems to automate complex industrial operations.

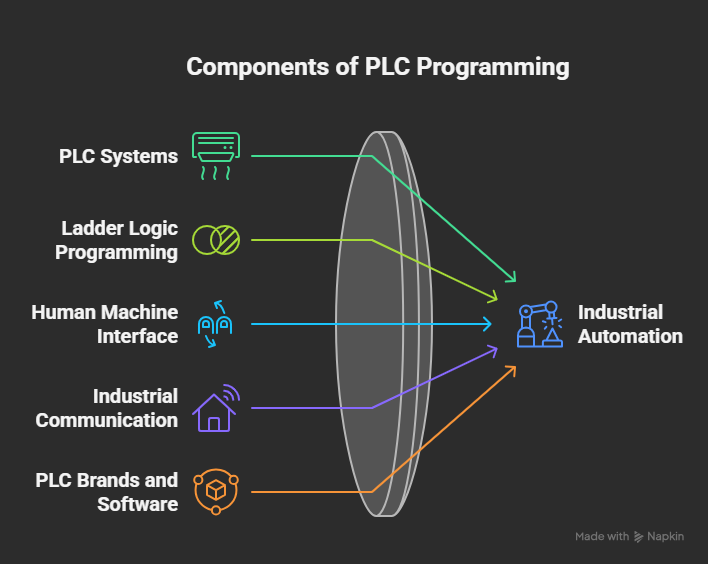

The architecture of a PLC system comprises several essential components working in harmony.

The Central Processing Unit serves as the brain, executing control programs and managing data flow.

Input and output modules interface with field devices, converting real-world signals into digital information that the CPU can process.

Communication ports enable PLCs to exchange data with other controllers, human-machine interfaces, and supervisory systems using industrial protocols.

Power supply units ensure stable operation even in electrically noisy environments characteristic of factory floors.

PLC programming employs specialized languages that differ significantly from conventional software development.

Ladder Logic remains the most widely used programming method, utilizing graphical representations that resemble electrical relay circuits, making the transition intuitive for electricians and technicians.

Function Block Diagrams offer another visual approach, connecting pre-built functional blocks to create control strategies.

Structured Text provides a high-level programming language similar to Pascal for complex mathematical operations and data manipulation.

Sequential Function Charts organize programs into steps and transitions, ideal for batch processes and machine sequencing.

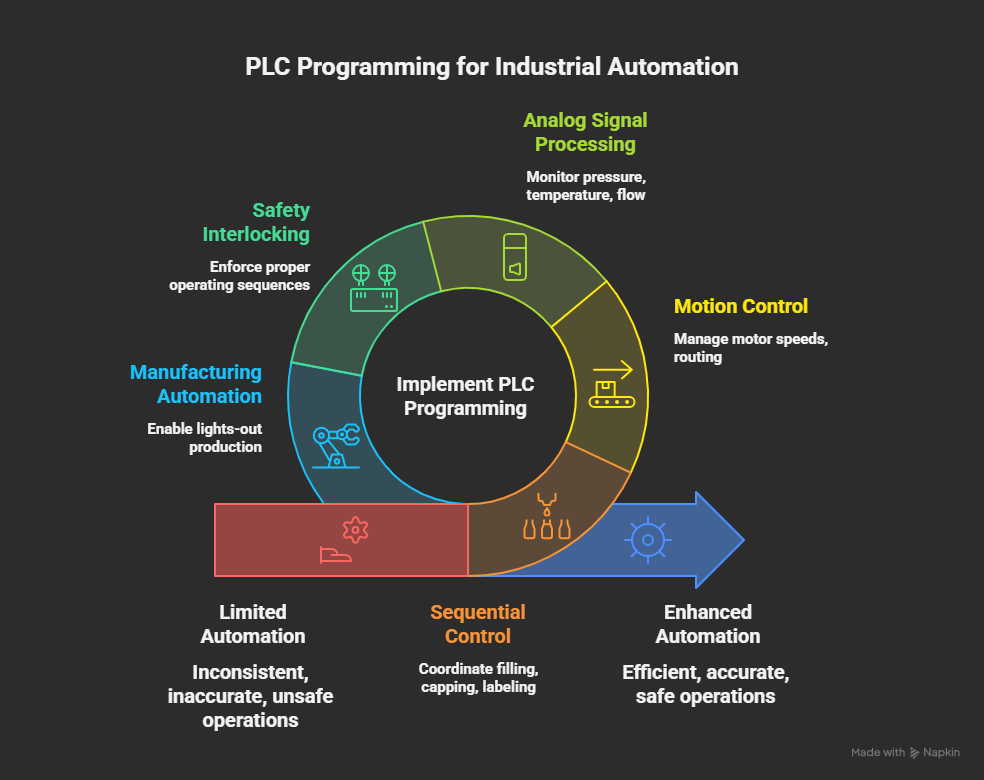

The versatility of PLCs extends across countless applications in modern industry. In bottling plants, PLCs coordinate filling, capping, labeling, and packaging operations with perfect timing.

Manufacturing assembly lines rely on PLCs to sequence robotic operations, monitor quality checks, and adjust production rates dynamically.

Oil and gas facilities use PLCs to control flow rates, maintain pressure levels, manage separation processes, and implement critical safety interlocks.

Power generation plants depend on PLCs for turbine control, load management, and automated startup-shutdown sequences.

Why Learn PLC Programming in Port Harcourt?

Port Harcourt’s strategic position as Nigeria’s industrial nucleus creates unparalleled opportunities for automation professionals.

As the operational headquarters for major oil and gas companies, including Shell, Total, ExxonMobil, and Chevron, the city hosts some of Africa’s most sophisticated industrial facilities.

Petrochemical refineries, liquefied natural gas plants, offshore platform support bases, and pipeline networks throughout Rivers State all depend heavily on automated control systems powered by PLCs.

Beyond petroleum operations, Port Harcourt’s expanding manufacturing sector presents growing automation needs.

Food and beverage processing plants require precise control of mixing, heating, cooling, and packaging processes.

Cement production facilities utilize PLCs for kiln control, material handling, and quality monitoring.

Water treatment plants serving the city’s population rely on automated systems for chemical dosing, filtration sequencing, and distribution management.

The Trans-Amadi Industrial Layout alone houses dozens of manufacturing operations transitioning from manual to automated processes.

The energy sector’s continuous expansion further amplifies demand for PLC expertise.

Power generation facilities, whether gas turbines or renewable installations, employ sophisticated control systems requiring skilled technicians for operation, programming, and maintenance.

As Nigeria pursues industrial diversification and increased local manufacturing capacity, Rivers State remains at the forefront of this economic transformation.

Every new factory, upgraded facility, and modernization project creates employment opportunities for professionals competent in industrial automation technologies.

Local engineering graduates and technical diploma holders often discover a significant skills gap between academic training and industry requirements.

Universities teach control theory and basic programming concepts, but rarely provide hands-on experience with the specific PLC brands, industrial protocols, and troubleshooting methodologies that employers value.

This disconnect leaves many qualified individuals struggling to secure positions in automation-related roles despite strong academic credentials.

Practical, industry-aligned training becomes essential for bridging this gap and accelerating career progression in Port Harcourt’s competitive job market.

Remtronic Automations PLC Programming Course Overview

The PLC Programming, Operation, and Troubleshooting course at RemtronicAutomations delivers comprehensive training structured to build competency from foundational concepts through advanced applications.

The program acknowledges that participants arrive with varying backgrounds, offering both Basic and Advanced tracks.

The Basic training spans one week with 24 hours of cumulative instruction time, providing intensive exposure to core PLC principles, programming fundamentals, and hands-on practice with multiple controller platforms.

The Advanced level, also delivered over one week with 24 hours of training, delves into complex programming techniques, system integration, industrial communication networks, and sophisticated troubleshooting methodologies.

Training objectives focus explicitly on employability and practical competence rather than mere theoretical knowledge.

Upon completion, participants gain the ability to interpret and develop ladder logic programs for five major PLC brands: Allen-Bradley, Delta, Omron, Siemens, and Schneider Electric.

This multi-brand approach reflects industry reality, where different facilities utilize varied automation platforms, and technicians must demonstrate versatility across equipment types.

Students learn not only to write programs but also to monitor system operations, identify faults through systematic diagnosis, implement modifications, and perform commissioning tasks with confidence.

The learning environment emphasizes hands-on engagement with actual PLC hardware rather than pure simulation.

RemtronicAutomations maintains a well-equipped laboratory featuring training kits with live PLC controllers, input-output field devices, communication interfaces, and process simulation panels.

Each participant receives dedicated access to equipment during training sessions, ensuring adequate practice time for skill development.

The small class sizes facilitate individualized attention from instructors who possess extensive field experience in industrial settings.

This instructor-to-student ratio allows for detailed explanations, immediate feedback on programming exercises, and mentoring that addresses each participant’s specific learning needs.

Course scheduling demonstrates flexibility designed to accommodate working professionals, students, and career changers.

Morning, evening, and weekend session options enable participants to pursue training without disrupting existing employment or academic commitments.

The intensive one-week format allows individuals to acquire substantial skills quickly, while the structured curriculum ensures comprehensive coverage despite the compressed timeline.

Entry requirements remain deliberately accessible to encourage broad participation from the technical community.

The course welcomes undergraduates and graduates of engineering disciplines, including electrical, electronic, mechanical, mechatronics, and chemical engineering.

Technical diploma holders with backgrounds in electrical installations, instrumentation, or industrial maintenance qualify for enrollment.

Even individuals from related technical fields can participate after assessment and validation by our senior training staff.

The fundamental prerequisite involves basic electrical knowledge and a genuine interest in industrial automation rather than prior programming experience, making the training accessible to career starters and career changers alike.

A valuable complementary component concludes the standard PLC course: an introduction to SCADA and HMI systems.

This addition recognizes that modern industrial automation rarely involves standalone PLC controllers.

Instead, PLCs typically interface with supervisory systems for data visualization, remote monitoring, and enterprise-level process management.

Understanding these connections prepares graduates for the integrated automation architectures they will encounter in actual industrial facilities.

Course Modules

Introduction to PLC Systems

The foundational module establishes essential understanding of PLC architecture, operational principles, and industrial applications.

Participants explore the historical evolution from relay-based control panels to programmable controllers, understanding the technological advantages that drove this transformation.

The instruction covers PLC hardware components in detail, examining central processing units, memory structures, input cards for various signal types, output modules with different switching technologies, and specialized cards for analog processing, high-speed counting, and motion control.

Distinctions between fixed and modular PLC architectures receive a thorough explanation, highlighting the practical implications for system design, expansion, and troubleshooting.

Students learn to identify PLC specifications, including scan time, memory capacity, input-output density, and environmental ratings, developing the ability to select appropriate controllers for specific applications.

Electrical wiring fundamentals for PLC installations cover power supply requirements, proper grounding techniques, input device connections, output load wiring, and electromagnetic interference mitigation strategies essential for reliable operation.

Ladder Logic Programming

Ladder logic represents the lingua franca of industrial automation, and mastery of this programming language forms the core of PLC competency.

The module begins with fundamental concepts, including contacts, coils, basic instructions, and program scan principles.

Participants learn to translate verbal control descriptions and electrical schematics into functional ladder diagrams, developing the conceptual thinking required for automation problem-solving.

Progressive lessons introduce timers, counters, comparison instructions, mathematical operations, and data manipulation commands.

Students practice creating programs for motor control applications, sequential operations, alarm management, and process interlocking.

The training emphasizes not just syntactically correct code, but also programming best practices, including proper documentation, structured organization, meaningful tag naming conventions, and efficient logic design that minimizes scan time and improves maintainability.

Simulation exercises allow participants to test their programs in a safe environment before deployment to physical controllers.

Debuggers, force functions, and online monitoring tools become familiar resources for validating program behavior and diagnosing unexpected outcomes.

The module culminates with troubleshooting scenarios where students must identify and correct faults in existing programs, developing the analytical skills that separate competent programmers from novices.

Human Machine Interface (HMI)

Modern industrial operations require intuitive visualization and operator interaction capabilities that PLCs alone cannot provide.

The HMI module introduces participants to panel-mounted touchscreen interfaces and computer-based operator stations that communicate with PLC controllers.

Training covers screen development software, navigation design principles, alarm configuration, trend displays, and security management for multi-user environments.

Practical exercises involve creating HMI applications linked to PLC programs developed earlier in the course.

Students design start-stop buttons, status indicators, setpoint entry fields, and real-time data displays that mirror actual industrial operator interfaces.

The integration between HMI and PLC through communication protocols receives detailed attention, ensuring participants understand tag addressing, data types, polling rates, and connection troubleshooting.

This module prepares learners to develop complete automation solutions rather than isolated PLC programs, recognizing that effective human-machine interaction significantly impacts operational efficiency and safety.

Industrial Communication

Industrial facilities rarely employ isolated controllers; instead, multiple PLCs, HMIs, variable frequency drives, sensors, and enterprise systems must exchange information reliably.

The industrial communication module demystifies the protocols and networking concepts that enable this connectivity.

Training covers Modbus RTU and Modbus TCP, perhaps the most widespread industrial protocols due to their simplicity and vendor-neutral specification.

Students learn to configure master-slave relationships, map register addresses, and troubleshoot communication failures using diagnostic tools.

Profibus, widely deployed in European-manufactured equipment, receives examination including network topology, device addressing, and data exchange mechanisms.

Ethernet-based industrial protocols, including EtherNet/IP and ProfiNet, demonstrate the convergence of automation and information technology networks.

Participants gain hands-on experience configuring communication parameters, establishing network connections, and exchanging data between different PLC brands, preparing them for the heterogeneous automation environments typical of modern facilities.

PLC Brands and Software

Recognizing that industrial automation lacks standardization across equipment manufacturers, Remtronic Automation’s training provides hands-on exposure to multiple PLC platforms representing significant market share in Nigerian industries.

Siemens TIA Portal receives substantial attention given the widespread deployment of Siemens S7 series controllers in oil and gas facilities, manufacturing plants, and infrastructure projects throughout West Africa.

Participants learn project creation, hardware configuration, ladder and function block programming, online testing, and documentation within the TIA Portal integrated engineering framework.

Allen-Bradley, now part of Rockwell Automation, maintains a strong presence, particularly in American-managed facilities and food processing industries.

Training with RSLogix 5000 or Studio 5000 software familiarizes students with ControlLogix and CompactLogix platforms, tag-based programming approaches, and add-on instructions that characterize the Allen-Bradley ecosystem.

Delta PLCs, favored for cost-effectiveness in smaller applications and Chinese-manufactured machinery, provide practical programming experience with WPLSoft software.

Omron and Schneider Electric platforms round out the multi-brand curriculum, ensuring graduates possess versatile skills applicable across diverse industrial settings.

Each software platform receives dedicated laboratory time where participants complete programming exercises specific to that brand’s syntax, addressing methods, and special functions.

This comparative exposure develops adaptability—the ability to quickly learn new PLC platforms when required by employment circumstances or project assignments.

Practical Applications of PLC in Industry

Understanding PLC programming achieves full value when contextualized within real-world industrial applications.

The training emphasizes how abstract programming concepts translate into tangible process control and operational improvements.

Bottling and packaging operations provide excellent examples of sequential control where PLCs coordinate filling valves, capping mechanisms, labeling applicators, and carton packers in precise timing sequences.

Students examine how sensors detect bottle presence, how counters track production quantities, and how quality reject systems remove defective products automatically.

Conveyor systems illustrate motion control applications where PLCs manage motor speeds, direction changes, accumulation zones, and automated routing based on product types or destinations.

Oil and gas process control demonstrates analog signal processing where PLCs continuously monitor pressure transmitters, temperature sensors, and flow meters, adjusting control valves through PID algorithms to maintain optimal operating conditions.

Safety interlocking receives special attention, given its critical importance in petrochemical environments where improper sequencing could create hazardous situations.

Manufacturing automation case studies showcase how PLCs enable lights-out production in automated factories.

Machine tools, robotic welders, automated guided vehicles, and quality inspection systems all operate under PLC coordination, exchanging information through industrial networks and responding to production schedules downloaded from enterprise systems.

These examples inspire participants by demonstrating the scope and significance of the skills they are acquiring.

The automation benefits that PLCs deliver extend beyond technical capabilities to fundamental business value.

Efficiency improvements result from eliminating human inconsistency, reducing cycle times, and maximizing equipment utilization.

Accuracy increases through precise timing, exact repetition, and error detection that surpass human capabilities in repetitive tasks.

Safety enhancements emerge from removing operators from hazardous environments, enforcing proper operating sequences, and implementing redundant protective measures.

Cost reduction follows from reduced labor requirements, decreased waste, lower energy consumption, and minimized downtime.

These outcomes explain why industries continue investing heavily in automation technologies and why skilled PLC programmers command attractive compensation.

Benefits of Remtronic Automations Training

Selecting the right training provider significantly impacts learning outcomes and career advancement.

RemtronicAutomations distinguishes itself through several meaningful advantages that address common weaknesses in alternative training options.

The hands-on laboratory experience stands paramount; participants work with actual PLC controllers, field devices, and process simulation equipment rather than relying exclusively on software simulations.

This tactile engagement with hardware develops confidence and troubleshooting instincts impossible to acquire through classroom lectures or computer-based training alone.

Small class sizes ensure individualized attention that transforms learning effectiveness.

Unlike training programs accommodating dozens of participants per session, RemtronicAutomations maintains intimate groups where instructors can observe each student’s work, provide personalized guidance, answer specific questions, and adjust pacing to the group’s progress.

This mentoring relationship continues beyond formal class hours as students gain instructor contact information for post-training consultation when encountering challenges in their early career assignments.

Recognized certification upon course completion provides documented evidence of competency, valuable during job applications and career advancement discussions.

The Remtronic Automations certificate carries local recognition among Rivers State industries familiar with the institution’s reputation and international credibility through alignment with standard PLC programming competencies.

Employers understand that certificate holders possess not just theoretical knowledge but verified practical skills tested through hands-on assessments.

Career guidance and internship opportunities extend the training center’s commitment beyond skill transfer to actual employment outcomes.

Staff maintain relationships with local industries requiring automation talent, facilitating introductions for qualified graduates seeking entry-level positions or career transitions.

Internship placements with partner companies allow recent graduates to apply newly acquired skills under professional supervision, building employment history and professional references that strengthen future job applications.

Comprehensive training materials, including detailed course notes, programming examples, reference documents, and instructional videos, remain accessible to participants long after course completion.

Software licenses for programming applications enable continued practice at home, reinforcing skills through repetition and experimentation.

This post-training support structure recognizes that skill mastery requires ongoing practice beyond the compressed training period, and RemtronicAutomations equips graduates with resources for self-directed development.

Training Venue & Facilities in Port Harcourt

RemtronicAutomations operates from its purpose-built training facility at 17 B Hon. Gideon Street, Off Peter Odili Road, Port Harcourt, Rivers State.

The location offers excellent accessibility from various city neighborhoods, with proximity to major thoroughfares facilitating convenient commutes for participants.

Adequate parking accommodates those driving personal vehicles, while public transportation options serve participants using taxis or buses.

The training center’s laboratory represents a substantial investment in educational infrastructure.

Multiple training stations equipped with different PLC brands allow simultaneous hands-on practice by all participants rather than observing demonstrations passively.

Process simulation panels replicate industrial scenarios, including motor control, level control, mixing operations, and traffic signal systems, providing meaningful contexts for programming exercises.

Testing instruments, including multimeters, signal generators, and communication analyzers, support troubleshooting training and electrical measurements instruction.

Classroom facilities feature proper ventilation, adequate lighting, comfortable seating, and projection equipment for effective presentation of theoretical content and software demonstrations.

The learning environment prioritizes participant comfort and concentration, recognizing that technical training demands sustained mental effort best supported by pleasant physical surroundings.

Industry partnerships enhance training relevance and employment connections. RemtronicAutomations maintains collaborative relationships with automation companies, industrial facilities, and engineering contractors throughout Rivers State.

These partnerships inform curriculum development, ensuring training content reflects current industry practices and emerging technologies.

They also create pathways for internship placements and employment referrals, benefiting graduates seeking to transition from training into career opportunities.

Certification & Career Opportunities

Successful completion of PLC Programming training culminates in certification documenting acquired competencies and training hours.

The RemtronicAutomations certificate specifies completion of the 24-hour Basic or Advanced program, listing covered topics and demonstrated proficiencies including ladder logic programming, multi-brand PLC experience, HMI basics, and industrial communication fundamentals.

This formal recognition provides tangible evidence of qualification when approaching prospective employers or seeking advancement within current organizations.

Career pathways for PLC-trained professionals span multiple job titles and responsibility levels. Entry-level positions include PLC Technician roles focused on controller maintenance, program documentation, minor modifications, and first-level troubleshooting in manufacturing facilities.

Maintenance Engineer positions in oil and gas, power generation, or processing plants increasingly require PLC programming competency as automation replaces relay-based control systems.

These roles combine mechanical and electrical maintenance responsibilities with control system support, offering attractive compensation packages and comprehensive benefits.

Control Systems Engineer represents an advanced career stage where professionals design automation solutions, develop programming standards, integrate PLCs with SCADA systems, and manage automation projects.

These positions command premium salaries reflective of specialized expertise and project management responsibilities.

Automation Specialist roles with system integrators or engineering contractors involve traveling to client facilities for commissioning new installations, upgrading existing systems, and providing technical support across diverse industries.

The industrial automation sector demonstrates consistent growth driven by ongoing factory modernization, new facility construction, and aging workforce replacement needs.

Port Harcourt’s industrial base ensures local demand remains robust even as the broader economy experiences fluctuations.

Oil and gas companies continually upgrade production facilities and implement advanced control strategies to improve efficiency and safety.

Manufacturing expansion, pursuing import substitution and export opportunities, creates greenfield installations requiring complete automation systems.

Power sector rehabilitation and renewable energy projects all incorporate PLCs extensively.

These trends project sustained employment demand for qualified automation professionals throughout the coming decade.

Real-world career progression examples illustrate the opportunities accessible to determined individuals.

Technical diploma graduates with PLC training have secured maintenance positions with oil servicing companies, advancing within several years to instrumentation supervisor roles, managing control system maintenance for offshore platforms.

Engineering graduates combining PLC skills with process understanding have joined multinational engineering contractors, eventually managing automation projects across West Africa.

Even career changers from unrelated technical fields have successfully transitioned into automation through intensive training, finding rewarding employment in industrial settings after years in stagnant career paths.

How to Enroll in Remtronic Automations PLC Programming Training

Prospective participants interested in developing PLC programming competencies can begin enrollment through several convenient methods.

Direct contact via phone at +234 803 768 3702 or +234 703 242 5572 connects inquirers with administrative staff who can answer questions regarding upcoming training schedules, payment options, and course specifics.

These numbers operate during business hours and welcome calls from anywhere in Nigeria or internationally for expatriates considering the training.

Physical visits to the training center at 17 B Hon. Gideon Street, Off Peter Odili Road, Port Harcourt allow potential students to tour facilities, examine laboratory equipment, discuss training objectives with instructors, and assess whether the program aligns with their career goals.

These consultations carry no obligation and help individuals make informed decisions about their professional development investments.

The enrollment process follows straightforward steps designed for efficiency and clarity.

Registration requires completing an application form providing basic demographic information, educational background, and professional experience to help instructors understand participant profiles.

Payment arrangements accept various methods, including bank transfers, online payments, and in-person cash or card payments at the training center.

Course fees cover all training materials, laboratory access, certification, and post-training support, with no hidden charges or unexpected expenses.

Class schedules maintain a regular training cycle, ensuring minimal waiting time between inquiry and course commencement.

New cohorts typically begin monthly, with specific start dates announced through the training center’s website, social media channels, and direct communication with registered participants.

The flexible scheduling accommodating morning, evening, or weekend preferences requires early registration to secure desired time slots, given limited class sizes.

Upon registration confirmation, participants receive preparatory materials including course overview documents, recommended preparatory reading, software installation instructions for those bringing personal laptops, and practical information regarding training location, parking, and session timings.

This pre-course communication ensures participants arrive ready to maximize learning from the first training session.

Join the next PLC Programming batch in Port Harcourt and transform your career prospects in Nigeria’s thriving industrial automation sector.

Whether you’re an engineering graduate seeking your first technical position, an experienced technician upgrading skills for career advancement, or a professional transitioning into the automation field, RemtronicAutomations provides the practical training and industry connections that convert learning into employment success.

Frequently Asked Questions (FAQ)

What is the duration of PLC training?

The PLC Programming, Operation, and Troubleshooting course at RemtronicAutomations is offered in two levels.

Both the Basic and Advanced programs span one week with 24 hours of cumulative instruction time.

This intensive format delivers comprehensive content through focused daily sessions that can be scheduled according to morning, evening, or weekend preferences based on participant availability and class enrollment.

Which PLC brands are taught?

The training curriculum provides hands-on experience with five major PLC brands representing significant presence in Nigerian industries: Allen-Bradley, Delta, Omron, Siemens, and Schneider Electric.

This multi-brand approach ensures graduates possess versatile skills applicable across the diverse automation platforms they will encounter in Port Harcourt’s industrial facilities.

Each brand receives dedicated programming exercises using the manufacturer’s authentic software tools.

Do I need prior experience?

No prior PLC programming experience is required.

The course welcomes undergraduates and graduates of engineering disciplines, technical diploma holders with electrical backgrounds, and other technically inclined individuals after skills assessment.

The fundamental prerequisite involves basic electrical knowledge and a genuine interest in industrial automation.

The curriculum builds from foundational concepts through advanced applications, accommodating participants regardless of prior exposure to PLC systems.

Is the training practical or theoretical?

RemtronicAutomations training emphasizes hands-on practical experience with actual PLC hardware, field devices, and process simulation equipment.

While essential theory receives appropriate coverage for conceptual understanding, the program’s distinguishing feature involves extensive laboratory work where participants physically wire controllers, develop programs, test logic, troubleshoot faults, and interface PLCs with HMI displays.

This practical focus ensures graduates possess job-ready skills validated through equipment operation rather than purely theoretical knowledge.

Will I get a certificate after completion?

Yes, successful course completion results in a RemtronicAutomations training certificate documenting your acquired competencies, training hours, and covered topics.

This certification provides formal recognition of your PLC programming qualification with both local acceptance among Rivers State industries and international credibility aligned with standard industrial automation competencies.

The certificate serves as valuable supporting documentation during job applications and career advancement discussions.

What career opportunities exist for PLC programmers in Port Harcourt?

Port Harcourt’s industrial base creates consistent demand for PLC-trained professionals across multiple sectors.

Career opportunities include PLC Technician positions in manufacturing facilities, Maintenance Engineer roles in oil and gas operations, Control Systems Engineer positions with engineering contractors, and Automation Specialist careers with system integrators.

The ongoing industrial modernization, new facility construction, and aging workforce replacement ensure sustained employment demand for qualified automation professionals throughout the region.

Can I practice at home after training?

Yes, participants receive comprehensive training materials, including programming examples, reference documents, and instructional videos for post-training review.

Software licenses or links to free manufacturer programming software enable continued practice on personal computers at home.

RemtronicAutomations encourages ongoing skill development through independent practice and remains available for consultation when graduates encounter challenges during self-directed learning or early career assignments.

Ready to master PLC programming and advance your career in industrial automation? Contact RemtronicAutomations today:

Address: 17 B Hon. Gideon Street, Off Peter Odili Road, Port Harcourt, Rivers State, Nigeria

Phone: +234 803 768 3702 | +234 703 242 5572.

Reserve your seat in the next training batch and join the ranks of skilled automation professionals driving Nigeria’s industrial future.